Sature is an environmentally friendly and nontoxic silicate modification process that makes wood stronger and last longer. We produce and sell SATURE impregnation liquid, surface treatment systems and - of course the know how that goes with it.

“ We have spent a decade developing and testing, which has resulted in this groundbreaking product we call Sature. ”

Sature is a new modification method for wood that replaces traditional pressure impregnation. It’s a new way of modifying wood that significantly expands its lifetime potential while minimizing the environmental footprint.

We use sand to make a silicat with the power to protect wood against decomposition. Once the Sature-treated wood has served its purpose it can be upcycled, re-used or disposed of as normal waste wood, without being classified as hazardous waste.

The purpose of impregnating wood is to increase the wood’s resistance to humidity. With traditional pressure impregnation, chemicals, often copper, chrome, and arsenic, are pressed into the wood. In Denmark, it is no longer legal to use chrome, arsenic, and a number of other heavy metals to impregnate wood. However, it is still legal to impregnate wood with copper, but it is not possible to separate it from wood impregnated with copper-chrome and can, therefore, not be burned after it has been discarded.

The heartwood is naturally better protected against humidity than the rest of the wood and it is, furthermore, not possible to reach that far into the wood. Some treatment products and processes render limited penetration into the wood and are far from reaching the core. The modification method with modified silicates is able to reach all the way to the heartwood. It cannot enter the core, but it reaches as far as other traditional impregnation methods on the market.

To test the properties of the modification process compared to other traditional products, Preservation Technologies has testing sites in France, Austria, Florida, and Malaysia. It is not the humidity that breaks down wood, but fungi that thrives in places with high humidity and warm temperatures. Denmark is only an ideal place for fungi 4-5 months of the year. To test the wood’s durability in Denmark will, therefore, take up to 12 years and require a good amount of patience.

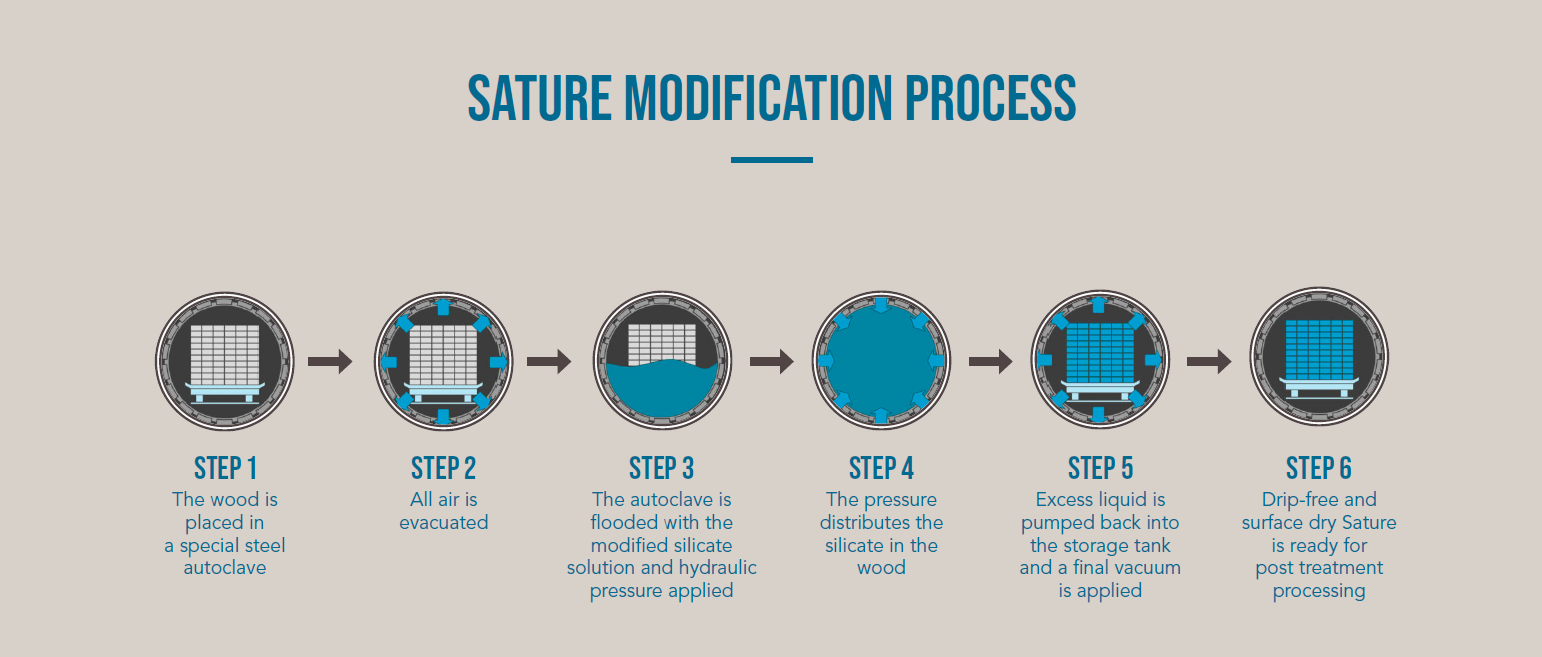

Wood is high pressure impregnated with an aqueous solution containing silicate. When the water from the treatment solution evaporates from the wood in a subsequent drying process, silicate agglomerates in the wood cell lumina acting as a physical barrier to water penetration (documented by CT scanning). Silicate particles do not penetrate the wood cell walls to any great extent due to

size restrictions in the ring pore membranes. The weight percent gain is approximately 20% in Scots pine sapwood. Heartwood is not penetrated except areas of high porosity such as close to the pith for example.

The silicate treatment has been shown to impart both water and moisture exclusion to the treated wood, which are well-known modes of action in wood modification technology (documented

by Dynamic Vapor Sorption (DVS) and liquid water sorption trials). A reduced water content and/or equilibrium moisture content in the wood makes the substrate less attractive for establishment of fungal growth. DVS data confirms a level of moisture exclusion in the range of 15-25% compared to untreated wood. Uptake of liquid water is roughly halved compared to untreated wood.